Product center

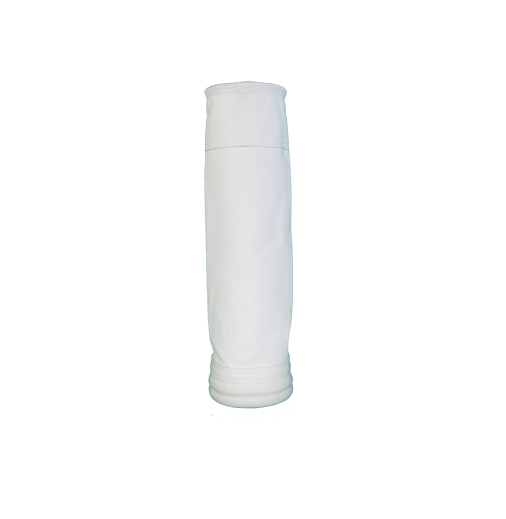

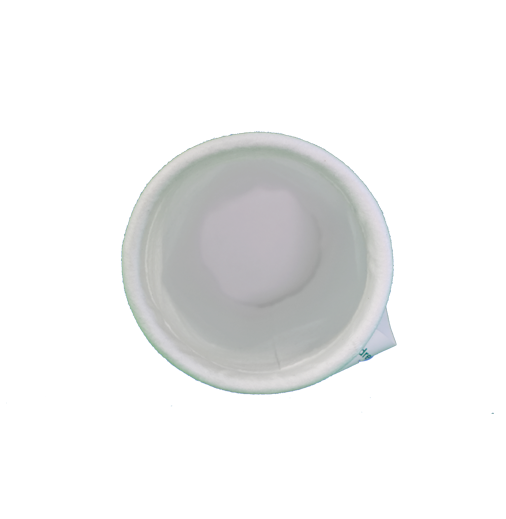

Polyester, polypropylene, acrylic, PPS, Aramid, P84, PTFE

What is spunky efficient filter material? Spines are a process of fiber consolidation through the use of fine high-pressure water jets. Nonwovens made in this way usually begin by combing the fibers into a network structure and then passing the mesh through a series of high-pressure water curtains that are used to entangle the fibers and create many fiber-to-fiber intersections. The technology is used to produce nonwovens with high fabric uniformity, high strength-to-weight ratio, lower average aperture and increased absorption properties. Hydraulic entanglement nonwovens. The process is designed to produce heavyweight fabrics in a variety of fibers (up to 18 oz /YD2=610GSM), specifically to produce filtration media for industrial filtration collection applications. Can produce polyester, aramid, PPS, PTFE and other commonly used fiber filter media. Compared with standard needle felt widely used in filtration industry, the performance is improved.

Want to know more? Please contact us.

Power plant

Chemical plant

Ironworks

Steel mill

Grain processing plant

Aluminum plant

Refractory plant

Cement plant

Carbon black plant

Ferroalloy plant

Foundry