Product center

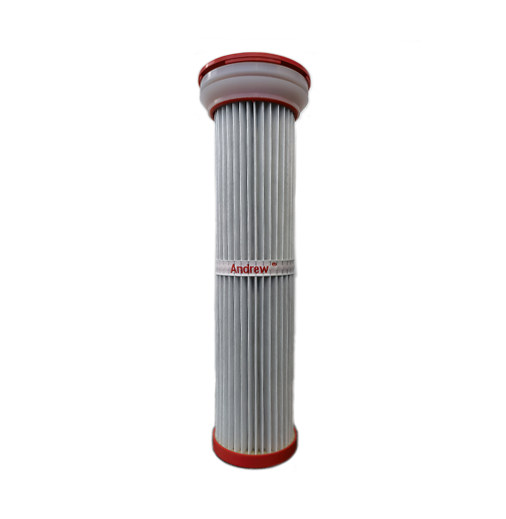

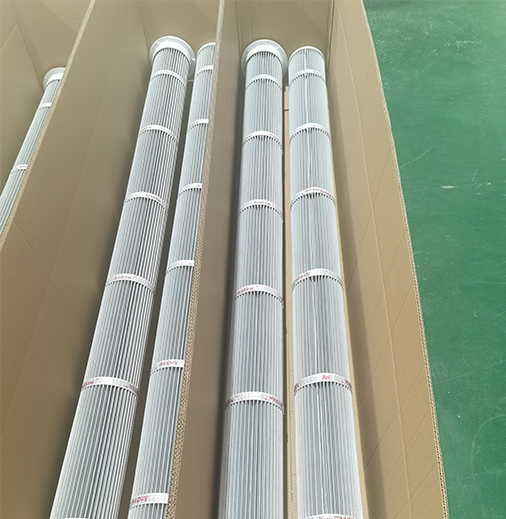

Developed to replace traditional filter bags and cage filters, each pleated duster is designed as a one-piece structure that can be used in new systems or simply modified in existing bag filter equipment to improve system performance. Pleated filter can provide more filter media than traditional felt bag, thus increasing the filter surface area and filter capacity. Life is 2-3 times longer than the traditional filter bag. The addition of folds in the design of pleated dust filter drum increases the filtration area almost twice as much as the filter bag in the existing equipment. When the airflow remains constant, the increased filtration area reduces the ratio of air to medium, thus improving filtration efficiency while operating at a lower differential pressure. A variety of installation methods, suitable for the top, bottom and oval configuration, and provide a variety of filter material options, including spina filter material, PTFE (polyester coating), polyester fiber, anti-static coating, flame retardant coating, carbon fiber materials, high temperature resistant materials.

Power plant

Chemical plant

Ironworks

Steel mill

Aluminum plant

Refractory plant

Cement plant

Carbon black plant

Ferroalloy plant

Foundry